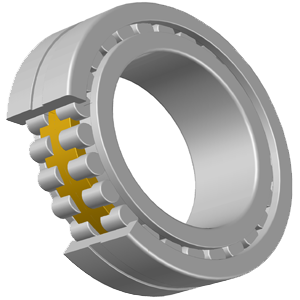

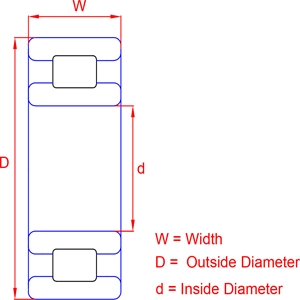

Cylindrical roller bearings are a type of rolling-element bearing designed to provide high radial load-carrying capacity and moderate thrust load-carrying capacity. These bearings consist of cylindrical rollers held between inner and outer rings called races. The cylindrical rollers are guided by the inner race and roll along the raceways of the inner and outer rings. Here's a breakdown of the key components and features of cylindrical roller bearings: 1. Inner and Outer Rings: Cylindrical roller bearings have two main rings—an inner ring and an outer ring. These rings are typically made of high-quality bearing steel or other suitable materials. 2. Cylindrical Rollers:The cylindrical rollers are the load-carrying components of the bearing. They are positioned between the inner and outer rings and are evenly spaced along the length of the bearing. The shape of the rollers is cylindrical, and they are in contact with the raceways of the inner and outer rings. 3. Cage: To maintain proper spacing and guidance of the cylindrical rollers, a cage is often used. The cage helps prevent the rollers from coming into direct contact with each other, reducing friction and wear. It also ensures uniform distribution of the load among the rollers. 4. Raceways: The raceways are the grooved tracks on the inner and outer rings along which the cylindrical rollers move. These raceways are precision-machined to provide smooth and accurate rolling motion. Cylindrical roller bearings offer several advantages, including: 1• High Radial Load Capacity: They can support heavy radial loads, making them suitable for applications with predominantly radial loads. 2• Moderate Thrust Load Capacity: While not primarily designed for axial loads, cylindrical roller bearings can handle moderate thrust loads. 3• Versatility: They come in various designs, including single-row, double-row, and multi-row configurations, allowing for versatility in different applications. 4• High Speeds: Depending on the design and configuration, cylindrical roller bearings can operate at high speeds. These bearings are commonly used in various industrial applications, such as in the automotive industry, machine tools, electric motors, and gearboxes, where radial loads need to be supported. The specific design and configuration of cylindrical roller bearings may vary based on the application requirements.

Types of Bearing

Cylindrical Roller Bearing

© 2024 Engineer Data. All rights reserved. | Privacy Policy | Terms of Service

Engineer Data application provides a comprehensive suite of engineering calculations, including:

• Spur Gear Cutting Calculation on Milling Machine

• Helical Gear Cutting Calculation on Milling Machine

• Worm and Worm Gear Cutting Calculation on Milling Machine

• Gear Train Calculation for Helical Gear Cutting on Milling Machine

• Simple Indexing for Milling Machine

• Gear Train Calculation of Differential Indexing for Milling Machine

• Taper Calculation for Lathe Machine Jobs

• Hole Dividing Calculation for Drill Machine

• Bearing Number Identification and search of boundary dimension

Improve your engineering projects with accurate and reliable data. For more information visit Engineer Data

Engineer Data application provides a comprehensive suite of engineering calculations, including:

• Spur Gear Cutting Calculation on Milling Machine

• Helical Gear Cutting Calculation on Milling Machine

• Worm and Worm Gear Cutting Calculation on Milling Machine

• Gear Train Calculation for Helical Gear Cutting on Milling Machine

• Simple Indexing for Milling Machine

• Gear Train Calculation of Differential Indexing for Milling Machine

• Taper Calculation for Lathe Machine Jobs

• Hole Dividing Calculation for Drill Machine

• Bearing Number Identification and search of boundary dimension

Improve your engineering projects with accurate and reliable data. For more information visit Engineer Data