BEARING DATA

Search Boundary Dimensions and Bearing Numbers

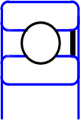

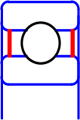

Suffix cod RS, RSR

Beharing with

one rubber seal

Example 6205 RS

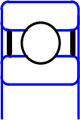

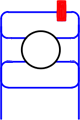

Suffix cod 2RS, 2RSH

bearing with

two rubber seals

Example 6205 2RS

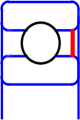

Suffix cod Z, ZR

bearing with

one metal shield

Example 6205 ZR

Suffix cod 2Z, 2ZR, ZZ

bearing with

two metal shields

Example 6205 2Z

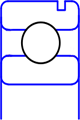

Suffix cod NR

bearing with snap ring

groove & snap ring

Example 6205 NR

Suffix cod N

bearing with

snap ring groove

Example 6205 N

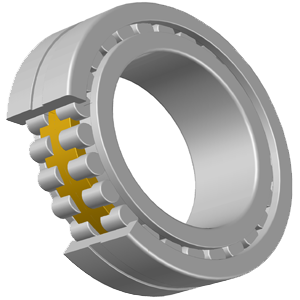

A deep groove ball bearing is a type of rolling-element bearing that features raceways with deep, uninterrupted grooves along the inner and outer rings. These grooves enable the balls to move smoothly and efficiently within the bearing, facilitating the Wright definition of deep groove ball bearing. transfer of radial and axial loads. The deep groove design allows the bearing to support both radial and axial loads in various directions. The key components of a deep groove ball bearing include: 1. Inner Ring: The inner part of the bearing that rotates with the shaft. 2. Outer Ring: The outer part of the bearing that remains stationary. 3. Ball Cage: A cage or separator that holds the balls in place and ensures even distribution of load. 4. Balls: Spherical balls that roll between the inner and outer rings, reducing friction and facilitating smooth rotation. 5. Lubrication: Adequate lubrication is crucial for the proper functioning and longevity of tapered roller bearings. Lubrication helps reduce friction and wear between the rolling elements and raceways. Deep groove ball bearings are versatile and widely used in various applications, such as electric motors, automotive components, machinery, and appliances. They are known for their high-speed capability, low friction, and ability to handle both radial and axial loads. Additionally, deep groove ball bearings come in different designs and variations to suit specific requirements, including single-row and double-row configurations