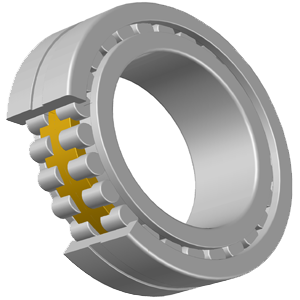

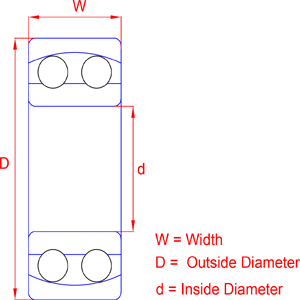

A self-aligning ball bearing is a type of rolling-element bearing that is designed to accommodate misalignment between the shaft and the housing without causing excessive friction or reducing bearing life. This type of bearing is particularly useful in applications where shaft deflection or misalignment may occur, such as in machinery with flexible shafts or in situations where there are mounting errors. Here's a breakdown of the design and functioning of a self-aligning ball bearing: 1. Double Row Construction: Self-aligning ball bearings typically have a double row of balls. This design allows the bearing to handle both radial and axial loads. 2. Spherical Outer Ring Raceway: The outer ring of a self-aligning ball bearing has a spherical raceway. This means that the outer ring is shaped like a part of a sphere. This feature enables the bearing to compensate for misalignment by allowing the inner ring and balls to adjust their position relative to the outer ring. 3. Self-Aligning Capability: The ability of the bearing to self-align comes from the combination of the double row of balls and the spherical outer ring raceway. This design allows the bearing to accommodate angular misalignment, shaft deflection, and housing distortions. 4. Cage:The balls in a self-aligning ball bearing are usually separated by a cage, which maintains proper ball spacing and alignment. Common cage materials include steel, brass, or polyamide. 5. Seals or Shields: Like other bearings, self-aligning ball bearings may have seals or shields to protect them from contamination and retain lubrication. 6. Internal Clearance: Self-aligning ball bearings are available with various internal clearances to accommodate different operating conditions. 7. Lubrication: Adequate lubrication is crucial for the proper functioning and longevity of a self-aligning ball bearing. Lubrication helps reduce friction and wear between the moving parts. 8. Applications: Self-aligning ball bearings are commonly used in applications where misalignment is expected, such as in conveyor systems, agricultural machinery, mining equipment, and various industrial machines. It's important to note that proper installation and maintenance are essential for the optimal performance of self-aligning ball bearings. They should be mounted with care to ensure that the self-aligning capability is utilized effectively, and periodic maintenance checks should be performed to monitor the condition of the bearings.

Types of Bearing

Self-Aligning Ball Bearing

© 2024 Engineer Data. All rights reserved. | Privacy Policy | Terms of Service

Engineer Data application provides a comprehensive suite of engineering calculations, including:

• Spur Gear Cutting Calculation on Milling Machine

• Helical Gear Cutting Calculation on Milling Machine

• Worm and Worm Gear Cutting Calculation on Milling Machine

• Gear Train Calculation for Helical Gear Cutting on Milling Machine

• Simple Indexing for Milling Machine

• Gear Train Calculation of Differential Indexing for Milling Machine

• Taper Calculation for Lathe Machine Jobs

• Hole Dividing Calculation for Drill Machine

• Bearing Number Identification and search of boundary dimension

Improve your engineering projects with accurate and reliable data. For more information visit Engineer Data

Engineer Data application provides a comprehensive suite of engineering calculations, including:

• Spur Gear Cutting Calculation on Milling Machine

• Helical Gear Cutting Calculation on Milling Machine

• Worm and Worm Gear Cutting Calculation on Milling Machine

• Gear Train Calculation for Helical Gear Cutting on Milling Machine

• Simple Indexing for Milling Machine

• Gear Train Calculation of Differential Indexing for Milling Machine

• Taper Calculation for Lathe Machine Jobs

• Hole Dividing Calculation for Drill Machine

• Bearing Number Identification and search of boundary dimension

Improve your engineering projects with accurate and reliable data. For more information visit Engineer Data